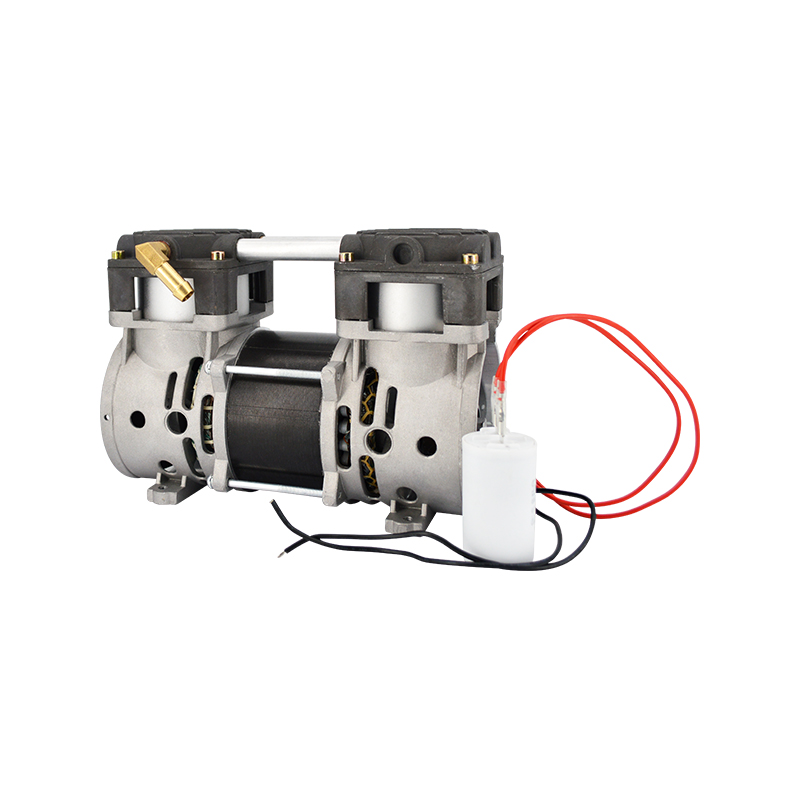

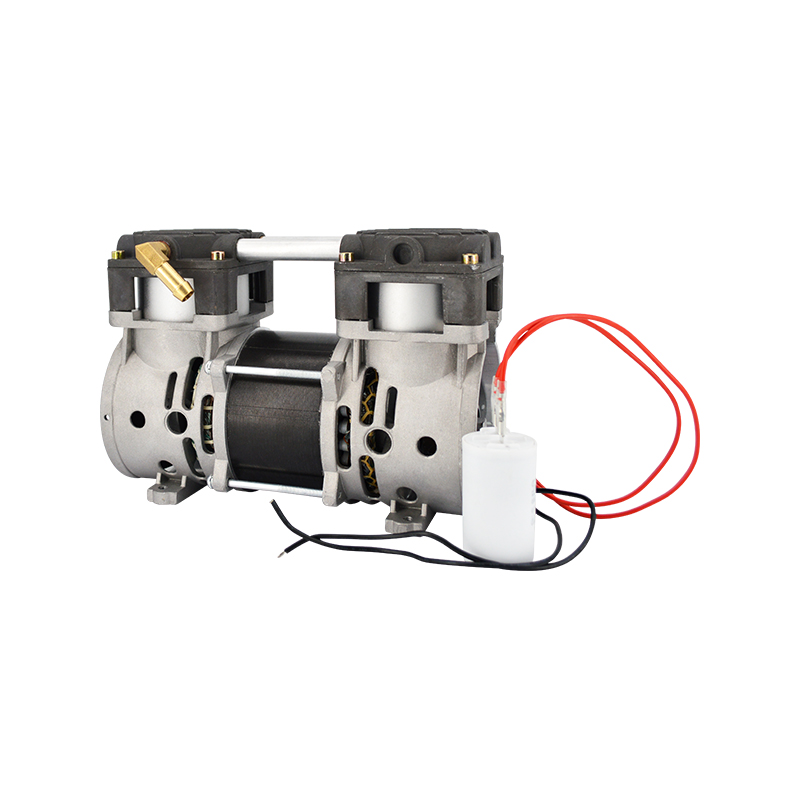

The stator and rotor in the air compressor pump are the key components of the motor.Their cooperation is the core of the motor to realize energy conversion and drive the normal operation of the compressor.

1.Stator

Function

•Generate a rotating magnetic field:The stator is usually composed of an iron core stacked by silicon steel sheet and an embedded electromagnetic coil.When energized,the coil of the stator produces a rotating magnetic field and drives the rotor to rotate.

•Provide fixed support:The stator is the stationary part of the whole motor,which is fixed in the moter shell to support the operation of the rotor and maintain its stability.

Value:

•High-efficiency electrical energy conversion:High-quality stator materials and structural design can reduce energy loss and improve the operating efficiency of the motor.

•Reduce the temperature rise:The optimized stator design (such as the use of high-quality wires and highly conductive materials) can effectively reduce current loss and hysteresis loss,thus reducing motor heating and extending the life of the equipment.

•Support multiple operating modes:In the variable frequency motor,the winding of the stator cooperates with the frequency converter to achieve precise control to meet the operation needs of the air compressor under different loads.

2.Rotor

Function:

•Realize mechanical energy output:The rotor is located inside the stator,driven by a rotating magnetic field and generates torque,and outputs mechanical energy to drive the crankshaft or rotor of the air compressor.

•Electromagnetic energy conversion:The rotor converts electrical energy into rotational motion through induction or DC excitation to complete energy transfer.

Value:

•High-efficiency mechanical movement:The optimized design of rotor structure and materials (such as copper rotor or aluminum rotor) can reduce electromagnetic loss and improve mechanical output efficiency.

•Low noise and smooth operation:The dynamic balanced rotor can reduce vibration and noise and ensure the stable operation of the compressor.

•Durability and adaptability:According to different working environments,rotors can adopt different materials and structures (such as mouse cage,winding,etc.)to meet various industrial needs.

3.The synergy of stator and rotor

The stator and rotor together constitute the electromagnetic system of the motor,which realizes energy conversion and transmission through electromagnetic induction or electromagnetic interaction.

•The rotating magnetic field generated by the stator deives the rotor to rotate,and the rotor transmits mechanical energy to other parts of the compressor.

•The cooperation of the two determines the efficiency,speed,stability and service life of the motor.

4.The specific value in the aie compressor

•Efficient drive:High-performance stators and rotors can significantly improve the overall efficiency of the air compressor,reduce energy consumption and reduce operating costs.

•Stability and reliability:The precisely designed stator and rotor can ensure that the compressor remains stable during long-term operarion and avoid downtime failure.

Adaptability:Different types of stator and rotor combinations are suitable for all kinds of compressors(such as piston type,screw type,etc.) to meet the needs of different industrial applications.

Conclusion:

The stator and rotor are the core components of the air compressor motor.The stator is respomsible for generating a magnetic field,and the rotor converts electromagnetic energy into mechanical energy.The two complement each other to ensure that the motor drives the compressor efficiently.Its design and performance directly affect the energy efficiency,reliability and service life of the air compressor,which is the basis for the stable operation of the equipment.

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик